Product Description

PURGE LINE FLUSH SET ACTUATOR VALVE screws directly to the can and attaches to the hose to inject Purge Line Set Flush into a system. It is reusable and since it does not pierce the can, product can be used on multiple jobs once the valve is removed. Purge System Flush is the industry’s all in one solution for cleaning up HVACR systems after burnouts, before refrigeration conversions, and new system/component installations. Purge has been designed to be a powerful but safe solvent that removes sludge, carbon residues, oils, acids, moisture and particulates from condensers, evaporators, and line-sets with no longterm environmental or health risks.

PURGE LINE FLUSH SET ACTUATOR VALVE screws directly to the can and attaches to the hose to inject Purge Line Set Flush into a system. It is reusable and since it does not pierce the can, product can be used on multiple jobs once the valve is removed.

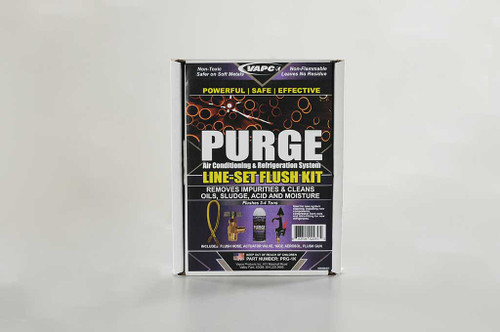

PURGE LINE FLUSH SET is a powerful, environmentally friendly, and economical solvent that is used to flush Air Conditioning and Refrigeration line sets during installs, cleanings, retrofits, change-outs or after burnouts. By seeing the solvents from boiling off too fast, the advanced formula removes more oil and other contaminants than any other flush. In addition to being available as a liquid, it is also available as a canister and flush kit. Flushes a wide variety of particulates from line sets when used such as sludge, carbon residues, acids, oils, and water. It is also ideal for change-outs, compressor burnouts, retrofitting to new refrigerants, and component changes.

Features and Benefits:

- Industry-standard for flushing, cost-effective

- No premature boil off, and leaves no residue

- Non-flammable, non-toxic

- Rinses away a variety of participants: sludge, carbon, acids, oils, and water

Directions:

GENERAL DIRECTIONS: Use in a well-ventilated area in temperatures above 60°F. Review the configuration of the system before using the product. Consider cleaning the condenser, evaporator, and line sets separately before application. For larger systems, disassemble and clean in sections. Then, remove filter driers/cores, bypass thermostatic expansion valves, compressor, accumulators, receivers, reversing valves, etc. Never inject into the compressor and if possible, crimp or restrict the line set. This allows for added vigor during the procedure. Be sure to use an open container to catch the oil and debris from the procedure.

DANGERS & PRECAUTIONS

Flammable. Vapors may be irritating to eyes, nose, throat, and lungs and may be harmful if swallowed. Wear safety glasses and gloves during use. Never connect the can to nitrogen or manifold sets. Failure to ensure system is pressurized (Free of Pressure) May cause can to burst and could result in injury.

HANDLING: Avoid contact with skin, eyes, and clothing. Avoid breathing vapors or mist.

STORAGE: Store in a cool place. Protect from contamination and keep the container tightly closed in a dry and well-ventilated place. Store in the original container. Avoid freezing temperatures. If stored below -10°C (14°F), mix prior to use.

WASTE DISPOSAL: The product should not be allowed to enter drains, watercourses, or the soil. All hazard precautionary measures should be followed.